Spray Research

EVAPORATING DIESEL SPRAY CHARACTERISATION

In diesel engine combustion, spray and resultant air-fuel mixing plays important role in efficient combustion emission formation. Thus, experimental data of spray characteristics under realistic experimental conditions is of significant value. In particular, when alternative fuels such as bio-diesels and emulsions are being considered for use in diesel engines, it is essential to understand their influence on spray characteristics.

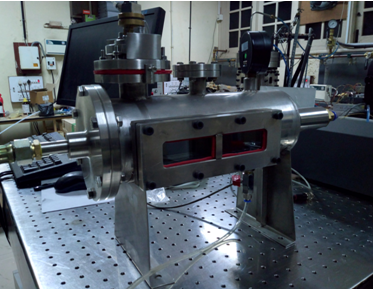

The high pressure spray chamber facility equipped with custom-made single hole diesel injectors, enables study of diesel and alternative fuel sprays in a 50 bar and 900 K nitrogen environment which is similar to in-cylinder conditions of a typical diesel engine at the end of compression stroke. A common-rail diesel injection system is used for fuel injection at injection pressure upto 1500 bar. High-speed shadowgraphy is used to obtain parameters such as liquid length, liquid penetration, vapour penetration. An exciplex-based PLIF method is used to measure the fuel concentration to understand local air-fuel mixing. The experimental data obtained under controlled experimental conditions is very useful for validation of CFD simulations. In the figures, the scale indicates distance from injector tip (in mm).

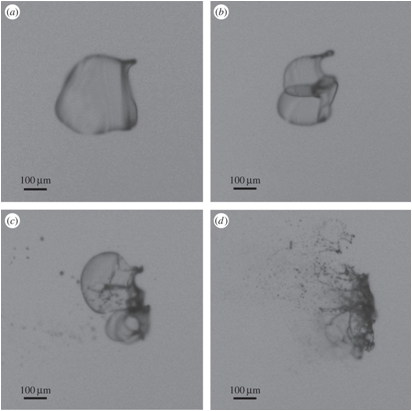

SECONDARY BREAKUP

Single drop breakup studies are being conducted to unravel more details on the underlying physics involved. The commonly known modes of breakup are:

(a) Bag breakup

(b) Bag-stamen breakup

(c) Multi-bag breakup

(d) Shear breakup

(e) Catastrophic breakup

Spray characteristics of the perforated cup type rotary atomizer, also called slinger atomizer, is studied experimentally. The fuel is atomized with the help of centrifugal force provided by the rotation of the slinger. The rotational power can be directly provided by the shaft of gas turbine. This type of injection system is very compact and hence suitable for small gas turbines. Present research is focused on studying the effects of liquid properties, rotational speed, liquid flow rate and geometric parameters of slinger on the spray characteristics. Studies of rotary atomization of non-Newtonian liquids for spray drying applications is also undertaken in the laboratory.

METHANOL-DIESEL EMULSION SPRAYS

Experimental investigation is carried out to study the effects of addition of methanol in diesel (methanol-diesel emulsions) on the fundamental spray characteristics. Different flow visualization and laser diagnostic techniques are used to evaluate the different spray characteristics such as liquid penetration, vapour penetration, spray cone angle and SMD. The experiments are carried out in the high-pressure spray chamber facility under engine-like conditions.

Computational studies are also carried out in the laboratory to model methanol and diesel sprays for applications in engines using the direct injection technology.